EVC1: Transesterification to biodiesel

Biodiesel (FAME) is produced from vegetable oils, animal fats, used cooking oils (UCO), greases and other fats and oils. Oils and fats mainly consist of triglycerides, i.e. three long (C10+) and straight fatty acid chain molecules linked to a glycerol (i.e. propanotriol, glycerine) molecule via ester functionalities.

The initial step in the FAME process is pre-treatment of the feedstock which for vegetable oils involves some procedures similar to the refining of edible vegetable oils. Tallow, other waste lipids, UCO, etc. include contaminants, in particular solids and unsaponifiables (sterols, protein residues, bone meal, etc.) that have to be removed in a fat treatment unit upstream of the main conversion step.

When using waste-based materials as feedstocks, there are a number of options how to deal with the free fatty acids (FFA) usually present in the feedstock. Biodiesel production facilities that are designed for the processing of vegetable oils can typically only cope with FFA contents up to 0.5%. In case of a FFA content up to 2-3 %, a neutralization together with the degumming step can be performed. Other plants use a FFA stripper to remove the FFA by steam stripping. This step can be realized for FFA contents up to 5-7%. Biodiesel plants designed for waste-based oils include an esterification step that allows the conversion of FFA into FAME. This step can be catalysed by different acids in the presence of an alcohol, or processes are performed at high temperatures and pressure with or without catalysts.

New processes realize the esterification (FFA) and transesterification step together at the same process conditions. These processes usually operate at higher temperatures and pressures.

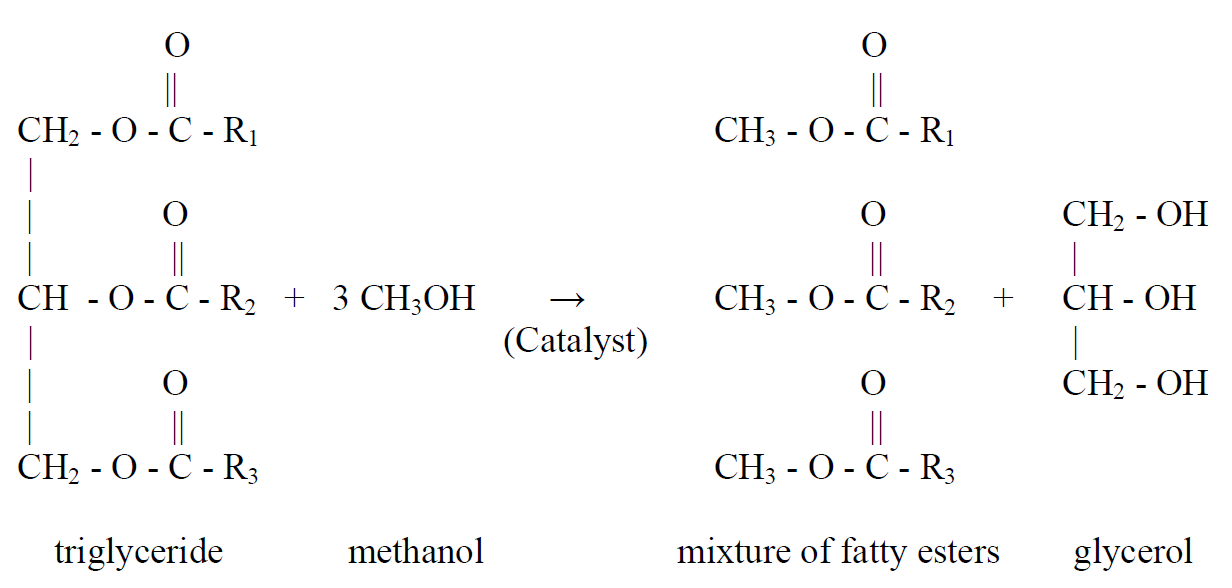

The pre-treated and purified triglyceride feedstock is processed by the transesterification reaction with an excess of dry methanol at atmospheric pressure and 60 °C, using a base catalyst[1], commonly sodium methoxide or potassium methoxide, at residence times of minutes followed by several hours of settling for phase separation. The transesterification reaction results in that the glyceride ester is reacted with methanol (approx. 10 %w of the triglyceride) to form three separate FAME methyl esters and in exchange the glycerol is released into the reaction mixture. The glycerol phase (approx. 10 wt% of the triglyceride) is separated by gravity or centrifuges and the glycerol/water/salt/ methanol mixture is subject to treatment to recover both methanol for recycling and a glycerol product[2] that can be a valuable by-product.

In most plants, the crude FAME is water washed to remove methanol, soaps and other impurities from the biodiesel. Afterwards the biodiesel is dried in a vacuum flash and remaining particles are removed by a filtration step or a centrifuge. In case of waste-based feedstock, after the flash dryer the biodiesel needs to be distilled to obtain a biodiesel complying with EN specification. In the distillation residue, components like unsaponifiables, glycerides, sulfur components, and metals are removed from the biodiesel.

Reaction equation of the transesterification process. Source: NREL 2004.

FAME biodiesel can be used as B100 but is more commonly blended into diesel at low blends, e.g. B7. Since the FAME chemical process has not affected the structure of the fatty acid chains, these are still straight and retain any unsaturation originally present, but also traces of glycerides that affects storage and use properties. For example, the choice of feedstock and it´s fatty acid distribution dictates the cold flow properties via the original triglyceride composition and must therefore be compatible with the climatic conditions of the intended market.

FAME biodiesel, subject to meeting the GHG reduction threshold, can in the EU be a biofuel or an advanced biofuel, eligible for double counting, depending on the feedstock used. Both categories can be produced in the same plant, if capable of using waste and residues materials.

Global production in 2017 was 36 billion liters[3] (328 TWh or 28 Mtoe). In 2016, the feedstock was 31 % palm oil, 27 % soybean oil, 20 % rape seed oil, 10 % UCO, 7 % animal fat and the balance other sources[4]. The EU (190 plants) is the main producer, 14 million liters production and with 21 billion liters installed capacity[5]. The second largest producer is the USA[6] (124 plants) 7 billion liters in 2017 based on 9 million installed capacity. Number three in production is Brazil (just over 50 plants) producing 5.4 billion liters but with 8.4 billion liters capacity[7], followed by Argentina and Indonesia providing 9 and 7 billion liters, respectively.

Fact Sheet: FAME

Acknowledgement: Large parts of the texts were taken from Lars Waldheim´s contribution to the report “The Contribution of Advanced Renewable Transport Fuels to Transport Decarbonisation in 2030 and beyond”

[1] In addition, there are processes based on heterogeneous catalysis and enzymatic reactions, but not in common use at present.

[2] Glycerol products traded range from crude glycerol (typically 80 % glycerol) to pharmaceutical grade (99.5-99.7 % glycerol)

[3] OECD‑FAO Agricultural Outlook 2018‑2027. Biofuels. OECD FAO 2018.

[4] UFOP Report on Global Market Supply 2017/2018. Union zur Förderung Von Öl- und Proteinpflanzen e.V.

[5] USDA Gains Report EU 2018

[6] biodieselmagazine.com/plants/listplants/USA

[7] USDA Gains Report Brazil 2018