Cellulosic Ethanol (CE)

An introduction to cellulosic ethanol technology

Demonstration and flagship projects on cellulosic ethanol:

- Beta Renewables / Biochemtex commercial cellulosic ethanol plants in Italy, Brazil, US and Slovak Republic

- Poet-DSM Project Liberty commercial cellulosic ethanol plant in US

- Abengoa Hugoton, Kansas commercial plant and MSW to ethanol Demonstration Plant, Salamanca

- Clariant – sunliquid® cellulosic ethanol demonstration plant, Straubing

- Inbicon Biomass Refinery for production of Cellulosic Ethanol

- Maabjergenergy Concept, Denmark

- BioGasol Demonstration Plant - BornBioFuel2

- Conversion of MSW and cellulosic materials to ethanol via gasification and synthesis

- Futurol pre-industrial pilot for cellulosic ethanol

- Chempolis Biorefinery for cellulosic ethanol

- St1 / North Bio Tech Oy cellulosic ethanol plant, Kajaani, Finland

- Borregaard production of ethanol from spruce

EC-funded R&D and Demonstration on cellulosic ethanol

- BEST and CEG Plant Goswinowice to be funded under NER300 first call

- EC-funded projects on Cellulosic Ethanol

- FibreEtOH Project

Development of enzymes and processes for cellulosic ethnaol production

- Enzymes for Cellulosic Ethanol production

- Petrobras Novozymes agreement on 2G ethanol from sugarcane bagasse

- TMO Process Demonstration Unit (PDU) for Cellulosic Ethanol

- ATENEA and PERSEO projects

Development of commercial cellulosic ethanol plants in North America and Brazil

- US Companies developing Cellulosic Ethanol plants

- Cellulosic Ethanol in Canada

- Commercial Scale Cellulosic Ethanol Plants in Brazil

Novel pathways to cellulosic ethanol

- Novel pathways to Cellulosic Ethanol

- Consolidated bioprocessing for production of Ethanol - Qteros and Mascoma

Use of Lignin

Introduction to cellulosic ethanol

Cellulosic ethanol is chemically identical to first generation bioethanol (i.e. CH3CH2OH). However, it is produced from different raw materials via a more complex process (cellulose hydrolysis).

In contrast to first generation bioethanol, which is derived from sugar or starch produced by food crops (e.g. wheat, corn, sugar beet, sugar cane, etc), cellulosic ethanol may be produced from agricultural residues (e.g. straw, corn stover), other lignocellulosic raw materials (e.g. wood chips) or energy crops (miscanthus, switchgrass, etc).

These lignocellulosic raw materials are more abundant and generally considered to be more sustainable, however they need to be broken down (hydrolysed) into simple sugars prior to distillation. This may be achieved using either acid or enzyme hydrolysis. Both approaches have been the subject of continuing research interest since the 1970s, and large investments are being made in the US and Europe to speed up development of this route to bioethanol.

First commercial scale cellulosic ethanol facilities went online in 2012 to 2016

The largest facilities currently are

- DuPont, Iowa, USA, 83,000 tons per year capacity, start-up in 2016, currently idle

- POET-DSM Advanced Biofuels, Iowa, USA, 75,000 tons per year capacity, start-up in 2014, operational

- Abengoa Bioenergy Biomass of Kansas, Kansas, USA, 75,000 tons per year capacity, start-up in 2014, currently idle

- GranBio, Alagoas, Brazil, 65,000 tons per year capacity, start-up in 2014, operational

- Longlive Bio-technology Co. Ltd, Shandong, China, 60,000 tons per year capacity, start-up in 2012, operational

A number of smaller demostration plants for production of cellulosic ethanol are operational or under development. In addition, a number of pilot plants are developing thermochemical/biochemical routes to create bioethanol from commercial waste and MSW. For more details check the ETIP Bioenergy Database on Production Facilities.

Normal 0 21 false false false IT X-NONE X-NONE /* Style Definitions */ table.MsoNormalTable {mso-style-name:"Normale Tabelle"; mso-tstyle-rowband-size:0; mso-tstyle-colband-size:0; mso-style-noshow:yes; mso-style-priority:99; mso-style-parent:""; mso-padding-alt:0cm 5.4pt 0cm 5.4pt; mso-para-margin-top:0cm; mso-para-margin-right:0cm; mso-para-margin-bottom:10.0pt; mso-para-margin-left:0cm; line-height:115%; mso-pagination:widow-orphan; font-size:11.0pt; font-family:"Calibri","sans-serif"; mso-ascii-font-family:Calibri; mso-ascii-theme-font:minor-latin; mso-hansi-font-family:Calibri; mso-hansi-theme-font:minor-latin; mso-ansi-language:DE; mso-fareast-language:EN-US;}- Download the EBTP

Value Chain Fact Sheet #5 Sugar to Alcohols (177 Kb)

Value Chain Fact Sheet #5 Sugar to Alcohols (177 Kb) - See the EBTP ethanol fact sheet for more technical information.

Flagship (first-of-a-kind commercial) and demonstration cellulosic ethanol facilities

M&G commercial scale cellulosic ethanol plants in Italy, Brazil, US and Slovak Republic:

Crescentino (Italy)

The Beta Renewables commercial scale cellulosic ethanol plant at Crescentino was officially opened on 9th October 2013. It is currently the world's largest advanced biofuels refinery with a production capacity of 75 million litres of cellulosic ethanol annually. The shareholders of Beta Renewables are Biochemtex, a company of the Mossi & Ghisolfi Group (M&G), TPG Capital, and Novozymes.

The plant is based on the patented Proesa™ process, and uses Novozymes enzyme technology to convert local wheat straw, rice straw and Arundo donax to ethanol. Lignin, extracted during the production process, is used at an attached power plant, which generates enough power to meet the facility’s energy needs, with any excess green electricity sold to the local grid.

Prior to the construction of BioCrescentino, Proesa™ process was optimised at the Rivalta Scrivia (Alessandria) pilot plant, which has a capacity of 1t/day of biomass treated.

![]() View short presentation on the opening of the commercial Crescentino Cellulosic Ethanol Refinery

View short presentation on the opening of the commercial Crescentino Cellulosic Ethanol Refinery

Previously, a presentation on the commissioning of the Crescentino plant was made at EBTP SPM5 in February 2013.

![]() Case study on the first commercial advanced ethanol plant in the EU, and how it was financed

Case study on the first commercial advanced ethanol plant in the EU, and how it was financed

Stefania Pescarolo, M&G Chemtex

COMETHA Project - Industrial scale pre-commercial plant, Porto Marghera, Italy

COMETHA (2014-2018), supported by FP7, involves the construction and operation of an integrated industrial facility for the production of second generation bioethanol and other co-products from lignocellulosic feedstock. The project builds upon the technology and processes demonstrated at Crescentino. Innovations include :

- Proprietary biomass pre-treatment unit;

- SSCF technology for the simultaneous saccharification of cellulose and hemicellulose and co-fermentation of glucose and pentose, with the use of novel high-performance enzymes;

- High-efficiency integrated distillation and dehydration system;

- Optimisation of feedstocks including dedicated perennial crops (Arundo donax) and agricultural residues

- Detailed life cycle assessment

GranBio, Alagoas (Brazil)

Beta Renewables technology is also being used at the GranBio Commercial Scale Cellulosic Ethanol Plant in Alagoas, Brazil (see below for latest details), which began production in September 2014.

Canergy, Imperial Valley (United States)

In May 2013, Canergy LLC announced that BioChemtex/Beta Renewables technology would be used for a 30 MMgy cellulosic ethanol plant in Imperial Valley, California. Canergy’s cellulosic advanced biofuel facility will begin production in 2016, and produce in excess of 30 million gallons per year of cellulosic ethanol from energy cane grown in the Imperial Valley of California.

In August 2012, it was announced that Chemtex International Inc. (Biochemtex) had received a conditional USDA loan guarantee to build a 20 MMgy cellulosic ethanol facility in eastern North Carolina using energy grasses as feedstock, also using Proesa™ technoloy. In July 2013, Chemtex International (Biochemtex) signed a long-term agreement with Murphy-Brown LLC, Warsaw, N.C., for supply of energy crops for the cellulosic ethanol facility at Clinton. The crops will be grown on land not used for grain production.

Strazske (Slovak Republic)

In October 2014, Beta Renewables and BioChemtex announced an agreement with Energochemica SE for the construction of a 55,000 metric ton commercial facility in Strazske, Slovak Republic, to produce cellulosic ethanol from non-food biomass. The plant will use enzymes from Novozymes and yeast from Leaf Technologies.

Fuyang (China)

In November 2013, Beta Renewables announced plans for a biorefinery in China that will convert straw and corn stover to ethanol and mono-ethylene glycol (MEG), which is used to produce polyester. The facility is a joint venture with Guozhen Group Co., and will be constructed in the Fuyang region, which has abundant agricultural residues available. The biorefinery will process 1 million metric tons of biomass per year, around 4 times the volume of BioCrecentino

Poet-DSM 'Project Liberty' - first commercial cellulosic ethanol plant in the US

POET-DSM Advanced Biofuels, LLC, is a 50/50 joint venture between Royal DSM, Netherlands, and POET, LLC. Based in Sioux Falls, South Dakota, the company is a cooperative effort to commercialize innovative technology to convert corn crop residue into cellulosic bioethanol.

In September 2014, Poet-DSM Advanced Biofuels LLC commenced production at the $275m 'Project Liberty' cellulosic ethanol facility. The plant will produce 20 MMgy per year of cellulosic ethanol from corn stover and cob, and shares infrastructure with the adjacent 50 MMgy ethanol plant.

Project Liberty construction timelapse.

Key facts about Poet-DSM Project Liberty:

- Capital costs are $275 million.

- Fuel from Project LIBERTY represents a GHG reduction of 85%-95% over gasoline.

- The plant employs more than 50 people directly, and biomass harvesting is creating another 200 indirect jobs in the community. In addition, hundreds of people were involved in the construction of the plant.

- The state of Iowa has estimated a $24.4 billion impact on the state over 20 years.

- Project LIBERTY will consume 285,000 tons of biomass annually from a 45-mile radius of the plant.

- Farmers remove approximately 1 ton of residue (~25%) per acre.

- Project LIBERTY will spend approximately $20 million annually purchasing biomass from area farmers, providing additional income to the farmers.

- Project LIBERTY will produce up to 25 million gallons of cellulosic bio-ethanol annually.

Suomen Bioetanoli Oy commercial cellulosic ethanol plant, Myllykoski, Finland

Poet and DSM are in discussions with Suomen Bioetanoli Oy on how to utilize process, yeast and enzyme technology from the respective companies for conversion of cellulose to bioethanol in Finland. In December 2014, the Ministry of Employment and Economy in Finland granted €30m to Suomen Bioetanoli Oy to support development of a 90 MMly commercial cellulosic ethanol plant at Myllykoski [Source: www.tem.fi and Poet DSM].

Abengoa ceases production at commercial plant Hugoton, Kansas, US

The Abengoa Cellulosic Ethanol plant, Hugoton, Kansas © Copyright Abengoa 'the energy of change' blog

In December 2015, Abengoa ceased production at its Hugoton plant, due to financial difficulties. In November 2015, Abengoa announced that it was trying to reorganise over $9 billion in debts before 28 March 2016, to avoid being forced to file for insolvency. The company's NASDAQ shares fell sharply following the announcement. On 24 December 2015 Abengoa "signed with financial stakeholders, under Article 5 bis of the Spanish Insolvency Law, a loan that will serve as an economic injection of 106 M€. Abengoa is protected under Article 5 bis of the Spanish Insolvency Law which, for a period of three months extendable to four, allowing the company to protect and preserve the company’s value while it works on the design and development of an appropriated viability plan for its future. Abengoa trusts the viability plan will increase the confidence of stakeholders to focus all efforts in the future of the company." [Source: Abengoa website].

In October 2014, Abengoa Bioenergy Biomass of Kansas held the official opening of its commercial plant producing of 25 Mgal (100 ML) of cellulosic ethanol and 21 MW of renewable energy from biomass (mixture of agricultural waste, non-feed energy crops and wood waste). The plant is located to the west of Hugoton, state of Kansas, and aimed to create 65 permanent jobs. Feedstock purchases within a 50 mile radius of the plant were estimated to exceed $400m per annum. The construction of the Hugoton plant began in July 2011 and it started producing ethanol in September 2014. Abengoa Bioenergy Biomass of Kansas sold its Hugoton cellulosic ethanol plant to Synata Bio for $48.5 million in 2016.

In June 2013, Abengoas inaugurated its "W2B" MSW to cellulosic ethanol plant in Salamanca, Spain. The plant has a capacity to treat 25,000 tons of municipal solid waste (MSW) from which it will obtain up to 1.5 million liters of bioethanol for use as fuel. The demonstration plant located in Babilafuente (Salamanca, Spain) uses W2B technology developed by Abengoa to produce second-generation biofuels from MSW using a fermentation and enzymatic hydrolysis treatment. During the transformation process, the organic matter is treated in various ways to produce organic fiber that is rich in cellulose and hemicellulose, which is subsequently converted into bioethanol.

© Copyright Abengoa

Abengoa 2G Ethanol Demo Plant in Salamanca

View at larger size >>

Previously, Abengoa provided its proprietary process technology and the process engineering design for a BCyL Biomass Plant in Salamanca. Managed by Abengoa, the biomass plant was completed in December 2008 and has been fully operational since September 2009. It was the world’s first plant to utilize this technology on such a scale. It is located within the Biocarburantes de Castilla y León plant, meaning that both facilities share common services and process chains.

This plant has been used to improve the design of the commercial plants to be constructed over the coming years, assess operating costs, identify bottlenecks and streamline operations.

The plant capacity is 70 tpd of lignocellulosic, biomass such as wheat straw, and is able to produce over 5 MMl of fuel grade ethanol per year.

The production process involves:

- Preparation of biomass

- Thermochemical pretreatment

- Enzymatic Hydrolysis and fermentation with enzymes and yeast

- Distillation to produce ethanol and a solid co-product

Abengoa's demonstration plant was supported by the 5th Framework Programme.

Abengoa also heads the LED (Lignocellulosic Ethanol Demonstration) project funded by the European Commission and developed by a consortium of five companies from four different countries, with a plant in Arance, France.

In 2012, Abengoa announced that its cellulosic ethanol technology would be used to produce ethanol from sugar cane cane straw and bagasse in Brazil, as part of the Industrial Innovation Program for the Sugar Energy Sector.

DuPont cellulosic ethanol facility, Iowa, US and planned plant in China

In December 2014, construction of the DuPont Cellulosic Ethanol LLC plant in Nevada, Iowa was nearing completion. The plant will produce 30MMgy of cellulosic ethanol from 590000 bales of corn stover. Murex LLC will market the ethanol. See Commercializing Advanced Renewable Fuel in Iowa for facts and figures.

In July 2015, DuPont also announced an agreement with Jilin Province New Tianlong Industry Co. Ltd, China, to develop a plant to produce cellulosic ethanol in Siping City, using residues from corn production in Jilin Province. The Chinese company will license cellulosic ethanol technology from DuPont and will use DuPont's Accellerase enzymes.

INEOS Bio, Indian River BioEnergy Center, US

Following earlier technical issues, in September 2014 INEOS Bio announced that the Indian River BioEnergy Center was being brought back on-line. The BioEnergy Center is a joint venture commercial demonstration project between INEOS Bio and New Planet Energy. At full capacity, it will have an annual output of eight million gallons (24kta) of cellulosic ethanol and six megawatts (gross) of renewable power.

Inbicon (DONG Energy) technology for commercial production of cellulosic ethanol

In December 2013, DONG Energy and Royal Dutch DSM announced the succesful demonstration of a combined fermentation of C6 and C5 sugars from wheat straw on industrial scale. The combined fermentation results in a 40% increase in ethanol yield per ton of straw, which can result in significant cost cuts in the production of second generation bio-ethanol. The joint work by DONG Energy and DSM was co-funded by the FP7 KACELLE project.

In March 2010, Great River Energy announced that it would use Inbicon technology in a $300m biorefinery to produce cellulosic ethanol primarily from 480 000 tons of wheat straw (and other agricultural residues) from a 70 mile radius. The refinery aimed to be operational by 2015. The lignin by-product was to be used to increase the efficiency of a nearby power plant [ Source: Great River Energy].

In Autumn 2009, Inbicon a subsidiary of DONG Energy started the construction of a demonstration plant in Kalundborg, Denmark to showcase the company's second-generation technology for large-scale production of ethanol from straw.

The Kalundborg plant (at the Asnæs Power Station) also demonstrates energy integration with a power station. Steam from the power plant cooks the straw, and residual biofuel from the ethanol plant is burned by the power plant. Since the cellolosic ethanol plant produces more energy than it consumes to convert the biomass, the end result is an energy surplus that brings down the cost for both plants and demonstrates the efficiency and financial viability of the Inbicon process

The demonstration used 4 tonnes of straw per hour, equivalent to 30,000 tonnes of straw per year. Danisco Genencor & Novozymes were pre-qualified as suppliers of enzymes. The output will be 4300 tonnes / 5400 m3 of ethanol per year. The plant was designed to produce 11,100 tonnes of molasses (65%DM) per year, which is currently used for feed, but could in future also be used for bioethanol or biogas production

DONG Energy signed a contract with Statoil, to purchase the first five million litres of Inbicon’s bioethanol.

© Copyright Inbicon

Model of Inbicon demonstration plant for production of cellulosic ethanol from straw View at larger size >>

Clariant – sunliquid® cellulosic ethanol demo, Straubing and FP7 SUNLIQUID Project to develop a large-scale demonstration plant

In recent years, Clariant (formerly Süd-Chemie), a global leader in the field of specialty chemicals headquartered in Switzerland, has been developing the sunliquid® process for the production of cellulosic ethanol from agricultural residues, which is ready to market.

Planned development of a large-scale demonstration plan (~€225 million) is partly supported by the EC FP7 SUNLIQUID Project (€23 million) 2014-2018, including participants from Austria, Germany and Hungary, with Clariant as the Coordinator.

In December 2014 Clariant announced positive results from its fleet testing sunliquid with Mercedes-Benz, whose BlueDIRECT engines are already able to use E20. During 2014, test fleet vehicles were fuelled with sunliquid at the Mercedes-Benz site in Stuttgart-Untertürkheim. At the Haltermann plant in Hamburg the cellulosic ethanol is mixed with selected components to form the innovative fuel, the specifications of which reflect potential European E20 fuel quality.

On 20 July 2012, the sunliquid demonstration plant was officially commissioned in the Lower Bavarian town of Straubing. The plant replicates the entire process chain on an industrial scale, from pre-treatment to ethanol purification, serving to verify the viability of sunliquid technology on an industrial scale. On an annual basis, up to 1,000 tons of cellulosic ethanol can be produced at this plant, using approximately 4,500 tons of wheat straw. Other feedstocks are also to be tested at a later stage.

© Copyright Clariant/Rötzer

Clariant sunliquid® demonstration facility

View at larger size >>

The biofuel obtained using this process is manufactured on an energy-neutral basis and boasts greenhouse gas savings of some 95% – 5% being attributable to the logistics chain which is calculated as fossil-based. The production costs can compete with those of first-generation bioethanol.

Firstly the feedstock, for instance wheat straw, undergoes mechanical and thermal pre-treatment. This results in the lignin separating from the cellulose and hemicellulose chains, allowing the enzymes to split into sugar monomers during the next step. The enzymes used have been optimised to a high degree by the company and specifically modified for each type of feedstock and the relevant process conditions. This ensures particularly efficient hydrolysis, giving rise to high sugar yields.

As a result of process-integrated enzyme production, enzyme costs can be reduced to a minimum. To this end, a small portion of the pre-treated feedstock is channelled off from the main mass to serve as a basic source of nutrients for special microorganisms which produce the enzymes. These are therefore created whenever and wherever needed, with no costs being incurred for transport, storage or processing and without being dependent on enzyme suppliers.

© Copyright Clariant/Rötzer

Clariant sunliquid® integrated enzyme production

View at larger size >>

Following hydrolysis, any remaining solid matter (mainly lignin) is separated out and incinerated to generate energy, leaving a sugar solution containing C5 sugars in addition to glucose, a C6 sugar. The sunliquid process makes use of a special fermentation organism which simultaneously converts both C6 and C5 sugars into ethanol by way of a one-pot reaction, consequently producing around 50% more ethanol than comparable processes, which are only able to convert C6 sugars.

The final unit process consists of purifying the ethanol produced. This is usually carried out by means of classic distillation which, however, calls for high energy input. Clariant has developed an energy-efficient, adsorption-based separation process which, by comparison, offers energy savings of up to 50%. As a result of optimising this and other process design features, it is possible to generate the energy needed for the entire process from accumulated residue (mostly lignin). No additional fossil energy sources are required. The total ethanol yield lies between 20 and 25% (theoretical maximum: 27%).

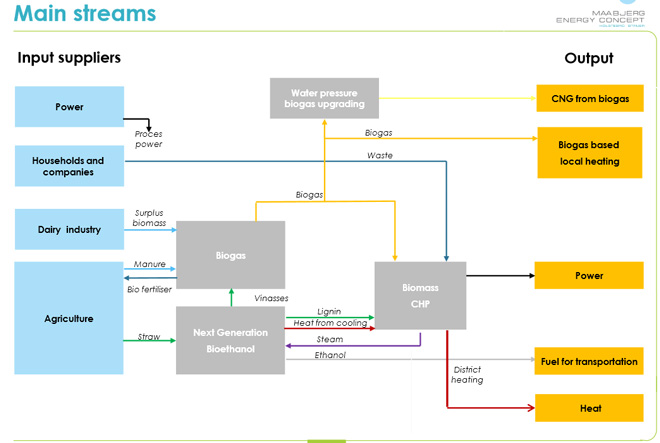

Maabjerg Energy Concept, Denmark

View presentation on Maabjerg Energy Concept made by Niels Henriksen, DONG Energy at EBTP SPM6, October 2014

© Maabjerg Energy Concept / Dong Energy

In June 2014, it was announced that the Maabjerg Energy Concept project would receive 39 million under the second phase of NER300. The project involves commercial-scale production of second generation ethanol from plant dry matter in Holstebro, Denmark. The plant will produce 64.4 Ml of ethanol, 77,000 t of lignin pellets, 1.51 MNm3 of methane and 75,000 t of liquid waste annually, which will be transformed into biogas and injected into the national gas grid after its upgrade into methane. The process will use 250,000 t/year of locally sourced straw.

In May 2015, Dong Energy entered into an agreement to concerning divestment of the Måbjerg wase-to-energy CHP Plant to Struer Forsyning Fjernvarme A/S and Vestforsyning Varme A/S. The divestment does not change the plans for the biorefinery Maabjerg Energy Concept where the CHP plant will use the biofuel 'lignin' from the biorefinery. The realisation of the Maabjerg Energy Concept depends on whether the Danish government introduces a requirement stipulating that at least 2.5 % second generation bioethanol should be added to gasoline in order to "create a market for the sale".

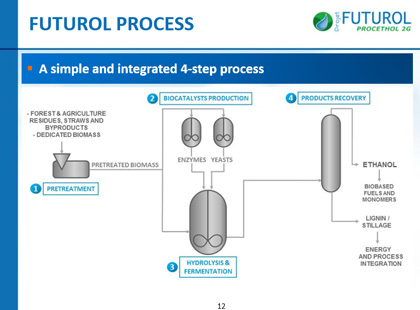

Futurol pre-industrial pilot plant for cellulosic ethanol production

Presentation on the FUTUROL pilot demonstration on cellulosic ethanol

made by Frédéric Martel, Procethol at EBTP SPM6, October 2014

In October 2011, the FUTUROL project announced the commissioning of its first pre-industrial pilot plant at Pomacle-Bazancourt, France. The plant, managed by Procethol 2G, validates research into second generation bioethanol carried out since 2008. The plant uses sustainable, local supply chains of feedstock including agricultural, forestry and other wastes. The plant on 1:1000 scale will produce 180,000 litres/year.

Futurol’s one-pot process allows simultaneous enzymatic hydrolysis of biomass and C5/C6 sugars fermentation which provides:

- CAPEX and OPEX minimization via a simple and integrated process

- A unique synergy between biocatalysts

- Full C5 and C6 sugars conversion

- High ethanol yield and content

© Futurol Project: from presentation made at EBTP SPM6, October 2014

TMO Renewables Cellulosic Ethanol Technology

In October 2012 TMO Renewables Ltd signed a 25-year feedstock supply contract with Usina Santa Maria Cerquilho, and in April 2013 signed an MOU with the company to build and operate a bagasse-to-cellulosic ethanol plant in Brazil. A 10 MMgy plant was scheduled to go into production ~ 2014, followed by construction of a larger plant. TMO Renewables has been supported in this project by BB2E Ltd UK.

In August 2012, TMO Renewables signed a Memorandum of Understanding (MOU) with the authorities of Heilongjiang, China, to secure long term large volume biomass feedstock supply for future biofuel production facilities from Heilongjiang State Farm, the largest state owned farming corporation in China. In May 2011 TMO Renewables announced technology partnerships with COFCO and CNOOC New Energy Investment in China to produce ethanol from cassava.

In 2009, TMO Renewables Ltd celebrated the first year of operation of its Process Demonstration Unit (PDU), the UK's first Cellulosic Ethanol plant. The PDU processed a wide range of cellulosic feedstocks, to demonstrate the commercial viability of TMO's unique pretreatment and fermentation technology based on a strain of bacteria found in compost heaps.

In Spain, IMECAL is working with CIEMAT and FORD Spain on the PERSEO pilot plant to demonstrate production of bioethanol from MSW. These partners, as well as AVEN, are also operating the ATENEA pilot plant to demonstrate the conversion of citrus wastes into cellulolsic ethanol.

![]() View ATENEA presentation from SPM2

View ATENEA presentation from SPM2

![]() View PERSEO presentation from SPM2

View PERSEO presentation from SPM2

In Norway, Weyland has developed a version of the Strong Acid Process in which 98.5% of the acid can be recovered and recycled. Ethanol production by this method is competitive and virtually any type of cellulose containing feedstock can be processed. Coniferous wood, rice straw, corn cobs and bagasse have been successfully tested.

Chempolis biorefinery for cellulosic ethanol

In November 2014, Chemopolis signed a Memorandum of Understanding (MoU) with Indonesia International Institute for Life-Sciences (i3L) to jointly promote and develop commercial biorefinery projects. In October 2014, Chempolis signed a partnership agreement with Numaligarh Refinery Ltd for a 'bamboo ethanol' project in India. The planned facility will convert bamboo into cellulosic ethanol, furfural and acetic acid

Chempolis, Finland peviously invested €20m in a biorefinery to produce cellulosic ethanol (as well as biochemicals and fibres) from a wide range of non-food biomass, particularly straw and bagasse. The biorefinery was opened by the Finnish Prime Minister, Matti Vanhanen on 4 May 2010. The plant can process 25000 t/a of raw material, and will also be used for testing raw materials and producing samples of bioethanol. The biorefinery processes are designed to be self-sufficient (with virtually no GHG production) and low in water consumption. The Chemopolis formicobio™ technology combines selective fractionation and efficient enzymatic hydrolysis followed by rapid fermentation. The biosolvent is completely recoverable, and the process requires a low level of enzyme input. [Source: Chemopolis].

St1 / North Bio Tech Oy cellulosic ethanol plant, Kajaani, Finland

In summer 2014, North European Bio Tech Oy (NEB) announced it would be investing in a €40m 10m l/y cellulosic ethanol plant at Kajaani, Finland, using local sawdust as a feedstock. The plant will be implemented and operated by St1 Biofuels Oy. Construction is due to start in mid 2015, with production scheduled to start by mid 2016. In May 2015, Novozyme announced it would be supplying enzymes to the project, which uses ST1's propietary Cellunolix® process (incorporating steam explosion and enzymatc hydrolysis). The production capacity of the plant will be leased to North European Oil Trade Oy (a sister company to NEB).

Petrobras Novozymes agreement on 2G ethanol from sugarcane bagasse

In October 2010, Petrobras and Novozymes entered an agreement to develop a new route to produce second generation biofuel from sugarcane bagasse. The agreement covers the development of enzymes and production processes to produce second generation lignocellulosic ethanol from bagasse in an enzymatic process.

"The commercial potential of cellulosic ethanol in Brazil is substantial due to the great amount of sugarcane bagasse, a fibrous residue of sugarcane production, available in the country. Brazil is the world’s largest sugarcane producer with an extraction capacity of approximately 600 million tons per year, currently yielding 27 billion liters (7 billion gallons) of ethanol. It is estimated that bagasse-to-ethanol technology can increase the country’s ethanol production by some 40% without having to increase the crop area" [Source: Novozymes].

Conversion of MSW and cellulosic materials to methanol/ethanol via gasification and synthesis

Enerkem commercial-scale production of ethanol from MSW via gasification

In June 2014, Enerkem inaugurated its commercial MSW-to-ethanol facility in Edmonoton, Canada. Enerkem, through its affiliate Enerkem Alberta Biofuels, signed a 25-year agreement with the City of Edmonton to build and operate the plant that will produce and sell next-generation biofuels from non-recyclable and non-compostable municipal solid waste (MSW). Sorted MSW is shredded and then fed into a gasifier, where heat and pressure create syngas, which is then cleaned and conditioned prior to catalytic conversion to methanol and ethanol. With a production capacity of 38 million litres per year (10 million gallons per year), the Enerkem Alberta Biofuels facility is the world's first major collaboration of its kind between a metropolitan centre and a waste-to-biofuels producer.

Initially, the plant will convert syngas to methanol. In 2015, a methanol-to-ethanol conversion unit will be added.

In November 2014, Enerkem announced a partnership with AkzoNobel to exploe the potential for producing biochemicals from waste in Europe.

BioGasol

In April 2012 BioGasol announced a partnership with Sweetwater Energy Inc., who will integrate the BioGasol pretreatment technology (Carbofrac™) into its systems to maximise sugar production from non-food biomass.

The BioGasol process converts straw and other lignoicellulosic agricultural residues into ethanol, biogas, hydrogen and solid fuel with minimum use of water and low production costs. The process features a thermochemical pretreatment and a unique fermentation process based on proprietary microbes, which convert both C6 and C5 sugars to ethanol. In March 2009, the Danish Energy Agency (ENS) Energy Technology Development and Demonstration Program (EUDP) awarded BioGasOl grant of 10.5 M Euros for the BornBioFuel2 demonstration plant on on Bornholm Island, using 27000 tonnes of dry feedstock to produce 7 Mio litres of ethanol per annum.

Pentoferm™ is BioGasol’s proprietary technology that optimizes the utilization of C5 sugars. Pentoferm™ enables the conversion of C5 sugars into ethanol using the thermophilic bacterium Pentocrobe™. With Pentoferm™ it is possible to achieve up to 40 percent higher ethanol yield from 1 tonne of biomass.

BioGasol previously formed a partnership wth Pacific Ethanol Inc to build the West Coast Biorefinery, in which BioGasol's technology was to be integrated with an existing corn-based bioethanol plant. The project was co-financed by the US DoE. The plant capacity was 5.8 tonnes of dry feedstock per hour (straw, hybrid poplar and cornstover), and aimed to produce 10 Mio litres of ethanol per year.

Range Fuels Two-Step Process

Also in the US, the Range Fuels Inc process uses heat, pressure and steam to convert cellulosic feedstocks (e.g. wood, grasses and corn stover) into syngas. In a second step the gas is passed over a proprietary catalyst to produce ethanol or methanol.

Two Cellulosic Ethanol projects to be funded under first NER300 call

BEST cellulosic ethanol project, Crescentino, Italy

On 18 December 2012 it was announced that the BEST project, Italy has been selected to receive counterpart funding of €28.4m under the first call for proposals of the NER300 funding programme for innovative low-carbon technologies. The Project concerns the design, construction and operation of an integrated biofuels demonstration plant in Crescentino (province of Vercelli, Piemonte region, Italy), at a distance of about 40 km from Turin. The Project envisages second generation technology conversion of lignocellulosic biomass from selected energy crops into ethanol. The Project proposes the cultivation and use of a new, autochthonous energy crop, Arundo donax (giant cane).The utilisation of wheat straw as an additional main lignocellulose biomass feedstock is also foreseen. The annual production capacity amounts to 51 Ml/year. Additionally, lignin will be produced as a by-product at some 165 t/year on wet basis.

CEG Plant Goswinowice, Poland

It was also announced that the CEG Plant Goswinowice, Poland has been selected to receive counterpart funding of €30.9m under the first call for proposals of the NER300 funding programme for innovative low-carbon technologies. The Project will demonstrate the production of second generation bioethanol from agricultural residues on a large commercial scale. The Project will make use of ~250000 t/year of wheat straw (75%) and corn stover (25%) sourced from the local agricultural area to produce 60 Ml/year of ethanol. The Project is located in Goswinowice in Poland close to an existing first generation ethanol plant. The Project plant and existing plant will be partially integrated. The co-products, lignin (70000 t dry matter lignin, moisture content 50-60%) and biogas (22.3 MNm3 biogas, 75% methane), will be sold as a fuel to the existing plant which in turn will provide steam for both plants.

[Source: SWD(2012) 224 final: NER300 - Moving towards a low carbon economy and boosting innovation, growth and employment across the EU]EC-funded R&D on Cellulosic Ethanol

2G BIOPIC (Horizon 2020) - The purpose of the 2G BIOPIC project - Second Generation BIoethanol sustainable production based on Organosolv Process at atmospherIc Conditions - is to demonstrate the performance, reliability and sustainability of the whole value chain of production of bioethanol from agricultural residues and wood. 2G BIOPIC (2015-2018) aims to design, construct and optimize a second generation (2G) demonstration plant with a capacity of 1 T of biomass/h. This 2G plant is based on the scale-up and optimization of bioethanol production from an already validated pilot plan scale (50Kg/h) achieved in a previous project (FP7 BIOCORE).

SUNLIQUID (FP7) aims to develop a large-scale lignocellulosic ethanol demonstration plan (~€225 million) with EC support of €23 million, 2014-2018. Includes participants from Austria, Germany and Hungary, with Clariant as the coordinator.

BABETHANOL - a collaborative research project between Europe and Latin America for the development of more sustainable processes for 2nd generation biofuel from lignocellulosic biomass (FP7 227498)

A short video presentation on the BABETHANOL project:

BABILAFUENTE- Project for the Production of 200 Million Litres of Bioethanol in Babilafuente (Salamanca) from Cereals and Lignocellulose (FP5 - NNE5 - 00685)

BIOCORE - Biocommodity refinery (FP7 BIOREFINE 241566)

BIO-HUG Novel bioprocesses for hemicellulose up-grading (FP5 - QLK3 - 00080)

Further information

BIOLYFE Demonstrating large-scale bioethanol production from lignocellulosic feedstocks (FP7-239204)

DISCO Targeted DISCOvery of novel cellulases and hemicellulases and their reaction mechanisms for hydrolysis of lignocellulosic biomass (FP7)

FibreEtOH Bioethanol from paper fibres separated from solid waste, MSW (FP7 239341)

HYPE High efficiency consolidated bioprocess technology for lignocellulose ethanol (FP7 213139)

KACELLE Kalundborg Cellulosic Ethanol Project (FP7). The aim is to bring the patented Inbicon Core Technology from a pre-commercial level to a near-commercial level, making the technology available in the market and attractive to investors (see also Inbicon Biomass Refinery below)

LED (Lignocellulosic Ethanol Demonstration) - Industrial solutions from a global bioethanol player

NEMO - Novel high performance enzymes and micro-organisms for conversion of lignocellulosic biomass to bioethanol

NILE- New Improvements for Ligno-cellulosic Ethanol (FP6 - 1982)

PROETHANOL2G - An EU-Brazil Collaborative project on Integration of Biology and Engineering into an Economical and Energy-Efficient 2G Bioethanol Biorefinery

Borregaard production of ethanol from spruce (SupraBio & EuroBioRef)

Cellulose producer, Borregaard, is involved in the development of biorefineries for the production of value-added products from wood, including bioethanol. Projects include supplying ethanol derived from spruce for 20 buses in Oslo. Borregaard was a key partner in the FP7 biorefinery projects Supra-Bio and EuroBioRef

The Borregaard demonstration biorefinery opened in April 2013, producing ethanol, lignin and added value biochemicals from wood, integrating a range of conversion technologies in a single facility.

FibreEtOH Project

The €16.26m collaborative FibreEtOH project ran from 2010-2013, with €8.65m support under FP7. The project was coordinated by UPM-Kymmenne. Other partners include AB Enzymes GMBH, Skandinavisk Kimiinformation AB, Poyry Forest Industry ConsulatingOY, Sila & Tikanoja OYJ, ST1 Biofuels, Roal and Valtion Teknillinen Tutkimuskeskus.

The innovative focus in the FibreEtOH project was to demonstrate for the first time globally in a commercial scale, a cost efficient paper fibre based ethanol production with high, > 70 % overall energy efficiency with high > 50 % green house gas reduction. 2nd generation ethanol production technology has been developed using mainly corn stover, straw or saw dust as raw material. So far reliable and cost efficient hydrolysis technology has been the bottleneck for large scale commercial success.

By using paper fibres separated from commercial and municipal solid waste or de-inking sludge at paper mills, the hydrolysis process was designed to be significantly easier as no pretreatment and special fractionation process was needed. The EtOH production cost was minimised by low price of the waste based raw material and the distillation steam compared to typical straw and wood EtOH production plants.

The results of the FibreEtOH project were published in Biomass and Bioenergy (Volume 46, November 2012, Pages 60–69). Ethanol and biogas production from waste fibre and fibre sludge – The FibreEtOH concept. The key results were as follows:

- Ethanol and biogas were produced in pilot scale

- Feedstocks were pulp and paper mill fibre sludge and waste fibre fractionated from solid recovered fuel

- Process was operated in continuous mode in high consistency conditions (substrate concentration 300 g kg−1).

- Liquefaction of the materials with enzymes was fast without any pre-treatment

- Total ethanol yield of 48% was obtained with 27 h residence time

Enzymes for Cellulosic Ethanol production

A number of companies are developing enzymes for cellulose hydrolysis including Novozyme, Denmark, which produces cellulase and hemicellulase. In September 2012 Novozyme announced it was considering marketing a C5 yeast strain developed by Terranol, Denmark for use in advanced biofuel production (for example, from corn stover hydrolysate).

In June 2013, Direvo Industrial Biotechnology GmbH announced it has been granted US and European patents for 'polypeptides with cellobiohydrolase II activity'. These offer higher performance compared to currently available cellulase enzymes, says Direvo.

In 2009, Syngenta entered into a collaboration agreement with Proteus, France to develop CE enzymes.

Codexis works closely with Shell and Iogen on enhacing the efficiency of enzymes for cellulosic ethanol production.

Dyadic optimises C1 Platform Technology for the development of novel enzymes to convert biomass into fermentable sugars to produce cellulosic ethanol and butanol as well as chemicals, polymers and plastics. Dyadic is currently a party to non-exclusive license agreements with Abengoa Bioenergy New Technologies, Inc. and Codexis, Inc. Following a 4-year demonstration project between Dyadic and SEKAB-E Technology (see DISCO Project) a new enzyme for cellulosic ethanol production AlternaFuel CMAX™ has been succesfully developed.

US Companies developing Cellulosic Ethanol plants and related technology:

Many of the companies developing cellulosic ethanol technology or demonstrations in the US are members of the Advanced Ethanol Council, which provides extensive information and data on the ethanol industry.

In July 2013, INEOS New Planet BioEnergy commenced commercial production at its 8M gallons-per-year cellulosic ethanol biorefinery at Vero Beach, Fla. This followed a $75 million loan guarantee from USDA. The plant also has a gross electricity production capacity of 6 MW. The feedstock for the process includes citrus and agricultural wastes, yard wastes and wood waste.

In September 2014, Poet-DSM Advanced Biofuels LLC commenced production at the $250m 'Project Liberty' cellulosic ethanol facility. The plant will produce 20 MMgy per year of cellulosic ethanol from corn stover and cob, and shares infrastructure with the adjacent 50 MMgy ethanol plant.

In December 2014, construction of the DuPont Cellulosic Ethanol LLC plant in Nevada, Iowa was nearing completion. The plant will produce 30MMgy of cellulosic ethanol from 590000 bales of corn stover. Murex LLC will market the ethanol. See Commercializing Advanced Renewable Fuel in Iowa for facts and figures.

Other examples of companies developing cellulosic ethanol technology include :

Cellerate, a collaboration between Syngenta and Cellulosic Ethanol Technologies LLC, a wholly owned subsidiary of Quad County Corn Processors. Cellerate enables corn kernel fiber to be converted into cellulosic ethanol, and the process technology can be readily added to existing ethanol plants as a bolt-on. In April 2015, Syngenta that Quad County Corn Processors has produced 1 million gallons of cellulosic ethanol using this technology. [Source: Syngenta 2014/2015].

In May 2013, American Process Inc. (API) announced investment from GranBio for cellulosic ethanol plants in the US and Brazil. API currently operates two demo plants in the US - the Alpena Biorefinery, and a facility in Thomaston, which uses API's 'American Value Added Pulping' AVAP process to convert a range of feedstocks to sugars.

Verenium (Vercipia). In September 2013, it was announced that Verenium would be acquired by BASF. In September 2010 BP Biofuels acquired the Verenium demonstration faclities in Jennings, LA, as well as cellulosic biofuels technology. In October 2012, BP announced that it has cancelled the planned construction of a commercial-scale cellulosic ethanol plant in Florida, and instead will focus on licensing its 2G technologies.

In January 2011, the USDA announced that "Coskata, Inc. received a letter of intent for a $250 million loan guarantee to construct and operate a cellulosic ethanol biorefinery facility. This 55-million gallon-per-year renewable biofuel project will use woody biomass to produce ethanol.

In Pontotoc, Miss., Enerkem Corporation received an $80 million loan guarantee to build and operate a biorefinery that will be capable of producing 10 million gallons of advanced biofuel (cellulosic ethanol) per year by refining some 100,000 metric tons of dried and post-sorted municipal solid waste through a thermo-chemical cellulosic process (see also Westbury demo below)."

California Ethanol & Power LLC Developing a facility able to produce 66 Mgy of ethanol, ~50 MW of electricity and 940M cubic feet of biogas, using sweet sorghum and sugar cane. The engineering will be led by Uni-systems do Brazil Ltda. Shell has signed a five-year offtake agreement for the electricity, biogas and ethanol [Source: CE&P October 2013].

Mascoma sold its yeast fermentation business to Lallemand Inc in 2014. Renmatix runs the Mascomas plant in Rome.

ZeaChem Operates an existing 250,000 GPY integrated demonstration biorefinery, at thePort of Morrow, near Boardman, and hasin February 2012 received $12 from USDA to further develop/demonstrate its biorefinery systems.

BlueFire Ethanol has developed commercial Concentrated Acid Hydrolyisis technology for conversion of cellulosic feedstock to sugars. BlueFire is currently in the process of developing two cellulosic ethanol facilities in Lancaster, California and Fulton, Mississippi. In October 2014, Bluefire announced an engineering, procurement and construction (EPC) contract for its 19 MMgy cellulosic ethanol plant in Fulton.

Bofuels Digest reported that after setting its sights on Brazil and bagasse in 2009 (after starting with Ponderosa pine), in 2010, KL Energy and Petrobras announced that they had entered into a Joint Development Agreement to jointly optimize KLE’s proprietary cellulosic ethanol process technology for sugarcane bagasse feedstock. As part of this agreement, The companies also said that they will develop a 4 Mgy bagasse-based cellulosic ethanol project that will be co-located with a Petrobras-owned sugarcane mill, which will come online in 2013..

Abengoa Bioenergy - Constructing a commercial-scale cellulosic ethanol plant in Kansas due to start production in 2014.

Edeniq's Pathway™ enzyme platform combines the Cellunator™ and unique enzymes to produce cellulosic sugars. In January 2015, Edeniq announced it had secured $16m in funding to further commecialize it's technology which can incease efficiency of exising ethanol plants by 3-6%. Previously in June 2012, Edeniq officially launched a Corn to Cellulosic Migration (CCM) pilot plant, which announced 1000 hours of continuous operation in May 2013.

Fiberight - Is developing commercial scale plants for conversion of MSW to ethanol

© Copyright POET

POET Cellulosic Ethanol Pilot Plant, Scotland, SD, US, producing 20,000 gallons per year using corn cobs as feedstock. The $8m pilot plant is a precursor to the $200 million Project LIBERTY, a commercial-scale cellulosic ethanol plant that will begin production in 2011. View at larger size >>

Commercial Cellulosic Ethanol Plants in Brazil

Granbio Cellulosic Ethanol plant, Alagoas

Following a 20-month construction, Brazil's first commercial-scale cellulosic ethanol plant at São Miguel dos Campos, Alagoas, began production in September 2014, with current production capacity of ~22m gallons per annum. The cost of the plant was $190m with a further $75m spent on the co-generation system. The plant uses Beta Renewables / Biochemtex PROESA technoloy. Novozymes supplies the hydrolytic enzymes, and DSM yeasts are used for the fermentation.

In May 2013, BNDES provided a $149m loan to Bioflex Agroindustrial, a subsidiary of GranBio, for construction of the plant, which will convert bagasse and residual sugar cane straw into 2G ethanol. BNDES said "The use of straw and bagasse will allow industrial productivity of ethanol to reach around 10,000 liters per hectare, corresponding to an increase of up to 45 percent compared to current levels."

GranBio intends to build a new ethanol plant each year up to 2020 with a planned investment of US$1.7 billion.

Raizen/Iogen Cellulsoic Ethanol Plant

In December 2014, production commenced at the $100 million, 40 MMly Raízen Energia S/A commercial Cellulosic Ethanol plant at the Costa Pinto sugarcane mill. The 10MMgy plant, uses technology developed by Iogen Energy, a joint venture of Raízen and Iogen Corp, to convert bagasse into ethanol. Enzymes are supplied by Novozymes. Raizen plans to producing up to 1 billion liters of cellulosic biofuel from bagasse and cane straw by 2024.

Cellulosic Ethanol in Canada

In June 14, Enerkem inauguarated a commercial-scale MSW-to methanol/ethanol plant in Edmonton Canada.

VANERCO, a joint venture between Enerkem and GreenField, plans to develop a cellulosic ethanol plant at the GreenField ethanol plant in Varennes, Quebec. In September 2013 it was announced that the project will receive some initial funding from the SDTC NextGen Biofuels Fund.

In June 2012, Enerkem started production of cellulosic ethanol from waste at its pre-commercial demo facility in Westbury, Québec, which uses an innovative thermochemical conversion technology.

In January 2014 Iogen announced a new method to produce drop-in biofuels from biogas. It plans to introduce the technology (alongside ethanol production) at its CE plants to increase overall production efficiency. In November 2013, it was announced that construction had started on a 10MMgy facility in Brazil using cellulosic ethanol technology of Iogen Energy, a joint venture of Raízen and Iogen Corp.. On April 30, 2012 Royal Dutch Shell and Iogen laid off 150 employees at Iogen's headquarters in Ottawa. Plans for a 10 MMgy cellulosic ethanol plant in Manitoba were suspended.

Shell had previously worked with Iogen (and Codexis) and the federal government to get Canada’s first commercial scale cellulose ethanol facility into production. Sustainable Development Technology Canada (SDTC), has been actively engaged in the transition of Iogen technology from development to commercialization.

© Copyright Iogen

World's first filling station offering Cellulosic Ethanol - 10% blend from wheat straw.

In 2014 Lignol Innovations Ltd (a subsidiary of Lignol Energy Corporation, Canada) was operating a Cellulosic Ethanol Development Centre in Vancouver, and was commissioning a pilot plant to produce bioethanol from lignocellulose (softwood, hardwood, agricultural residues). The technology was based on an ethanol-based organosolv process aquired from Repap Enterprises (bought by UPM Kymmene in 2000). Lignol signed an agreement with the US DoE for construction of a commercial demonstration plant (up to $30m). The plant was being planned with Suncor Energy, and had a projected input capacity of 100 tonnes a day [Source: IEA Bioenergy]. In December 2015, Natural Resources Canada announce that its ecoenergy innovaton initiative (EcoEII) had awarded $1,100K towards Lignol’s project “Production and Conversion of Biorefinery Cellulose to Advanced Fuels, Biochemicals and Biomaterials” to investigate and confirm the novel EH process at lab scale, as well as the potential for the production of valuable co-products.

Cellulosic Ethanol technology - Ongoing Research and Novel Pathways

In April 2015, Leaf Resources Ltd, Australia, launched Hybritech technology, based on it's Glycell pre-treatment process. Hybritch allows paper and pulp facilities to switch between pulp production and the production of cellulosic sugars, and is particularly suited to plants using the KRAFT process.

Xylome offers unconventional yeasts that can produce second generation ethanol (as well as biodiesel precursors) from cellulosic feedstocks. The company also modifies a range of unconventional yeasts for biosynthesis of advanced products. Unconventional yeasts have metabolic capabilities that go well beyond Saccharomyces in substrate utilization and product formation profiles (for example, those that are naturally able to ferment xylose and cellobiose).

Oklahoma State University Biobased Products and Energy Center (BioPEC) is developing hyprid gasification / fermentation pathways for production of ethanol, which it claims significantly lower the production cost of CE.

BE-Basic is developing a unique multi-purpose Bioprocess Pilot Facility BPF at Delft in the Netherlands, where companies, universities and knowledge institutions can investigate and learn how sustainable production processes respond to larger scales and how they can be scaled up. In Jann uary 2014 BPF announced it would be installing a prehydolysis system from Valmet.

In January 2014, French company Deinove announced the successful production of 9% ethanol from lignocellulosic feedstocks using Deinococcus bacteria in medium-sized (300 litre) bioreactors. The company now plans to develop the technology at industrial scale. The technology was developed through the Deinol project, which involved CNRS Montpellier and INSA Toulouse and the Tereos group (via its SYRAL and BENP Lillebonne subsidiaries). The Deinol project received €8.9m from the Strategic Industrial Innovation programme run by Oséo, the French state innovation agency. In November 2014, it was announced that Deinove had formed a partnership with Michigan State University to use its AFEX (ammonia-based pre-treatment) in production of cellulosic ethanol.

In February 2014, Aphios was granted US patents for its cellulosic biomass pretreatment method based on the Aosic process, in which "biomass is contacted with super fluids such as carbon dioxide with or without small quantities of polar cosolvents such as ethanol, both sourced from the downstream fermentation process. Pressure is released and fibers are made more accessible to enzymes as a result of expansive forces of super fluids (about 10 times those of steam explosion) and carbonic acid hydrolysis."

In February 2014, Leaf Energy (now Leaf Resouces Ltd), Australia, announced a succesful trial of Glycell Pretreatment Process, at the Andritz pilot plant, Springfield, Ohio. At that time, Leaf Energy was also working with Actinogen Ltd to exploit strains of Actinomycetes relevant to its technology. In 2016 Leaf Resources Ltd was collaborating with Claeris, ZeaChem, Monaghan Biosciences (part of the Monaghan Mushroom Group) and Norske Skog.

Researchers at North Carolina State University are developing the use of protic ionic liquids, PILs, as a less-expensive method to remove lignin from cellulosic biomass.

In August 2013, US DOE Joint BioEnergy Institute announced the development of a 'one-pot' process for the ionic liquid pretreatment and saccharification of switchgrass.

Consolidated bioporcessing aims to simplify biofuel production pathways by integrating the steps of pre-treatment, hydrolysis and fermentation as far as possible. Companies working in this technology include Mascoma and Qteros.

The Qteros CBP platform leverages the natural advantages of the Q Microbe®, which produces virtually all the enzymes required to digest biomass into fermentable sugars and contains all pathways required for biomass conversion into ethanol. The result is a single-step conversion process that dramatically reduces the cost and complexity of producing cellulosic ethanol at commercial scale from a broad variety of non-food feedstocks [Source: Qteros].

Researchers at the University of Illinois have investigated the use of "switchable" butadiene sulfone in the presence of water as a potential pretreatment method to break down the cell wall in Miscanthus, and remove the lignin component. Subsequent recovery of the decomposition gases, reduces cost and environmental impact.

OSE0 (Strategic Industrial Innovation Programme), France awarded €8.9m to the €21.4m DEINOL project, which aims by 2014 to open up new pathways for lignocellulosic ethanol production in existing industrial installations, without the need for large additional capex. The OSEO award included Euro €6m to Deinove for the accelerated development of new biofuels production processes based on the bacteria Deinococcus. The other partners include CPBS (CNRS/University of Montpellier) and LISBP (INSA Toulose/CNRS/INRA),

Green Tech America is developing cellulosic ethanol technology using novel strains of yeast. The process is based on research by Laboratory of Renewable Resources Engineering (LORRE), Purdue University, which developed GM yeasts in the 1990s to convert glucose and xylose to ethanol.

In Austria, M-Real Hallein AG is developing a concept to produce bioethanol from wood sugars derived from sulfite spent liquor (SSL), a by-product of paper and pulp production.

In November 2009, Delft University published research on GM strains of Saccharomyces cerevisiae that have been engineered for use of acetic acid as an electron acceptor. The pathway would provide three major benefits for production of ethanol from lignocellulosic materials: elimination of glycerol, reduction of toxic acetic acid to ethanol, and increased ethanol yields. A patent was applied for and industrial partners were being sought to further investigate the potential of the process.

Use of Lignin

The pretreatment processes described above breaks down lignocellulosic feedstocks into:

- hemicellulose, which is then hydrolysed by enzymes/acid to produce fermentable sugars for ethanol production

- lignin, the 'woody component'

Lignin has a number of potential uses, including:

- as a solid fuel

- as biofuel additives (e.g. conversion to oxygenated aromatics or esters)

- to add strength to concrete

- as an antioxidant

- to provide thermal protection to rubber

- for production of carbon fibre, asphalt mixes, plastics and polymers

- use as a paper sizing agent or board binder

- as a soil binder, as a dispersent for pesticide/herbicide applications, and similar agricultural uses

To improve the economics of cellulosic ethanol production in biorefineries, researchers are looking for ways to add value to lignin by conversion to other products (e.g. bio-oils contatining aromatic compunds). Coversion technologies include use of solvents, hydrothermal depolymerisation, and super critical depolymerisation.

In 2015, The US National Renewable Energy Laboratory published a study in the journal Energy and Environmental Science on the conversion of lignin-derived compounds to adipic acid, which is used to to produce nylon, plasticizers, lubricants, polyesters, etc.

In 2014, researchers at University of Wisconsin-Madison (funded by the Great Lakes Bioenergy Research Center), showed that high yields of the aromatics may be obtained by exposure of lignin to oxygen followed by treatment with a weak acid under mild conditions.

Reseachers at University of Tokyo have developed a technology using hydroxycyclopentadienyl iridium complexes as catalysts under hydrogen (dihydrogen) at atmospheric pressure to convert componens of lignin to aromatic chemicals [February 2015].

The University of Bath, UK has investigated ozonolysis in the presence of ethanol to depolymerise lignin, resulting in production of oxygenated aromatics. "Guaiacol, a potential antioxidant, was formed over short reaction times and was found to be completely miscible with low-sulphur petrol (ULSP), diesel, aviation kerosene and rapeseed methyl ester. The mainly aliphatic proportion of the bio-oil produced over 24h could be blended with the fuels replacing a maximum of 12-17wt.% of the hydrocarbon fuel." [Source: Renewable biofuel additives from the ozonolysis of lignin].